Over 100 years old and still moving forward

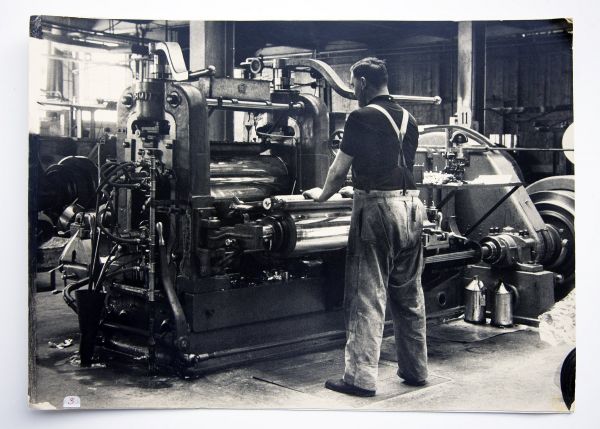

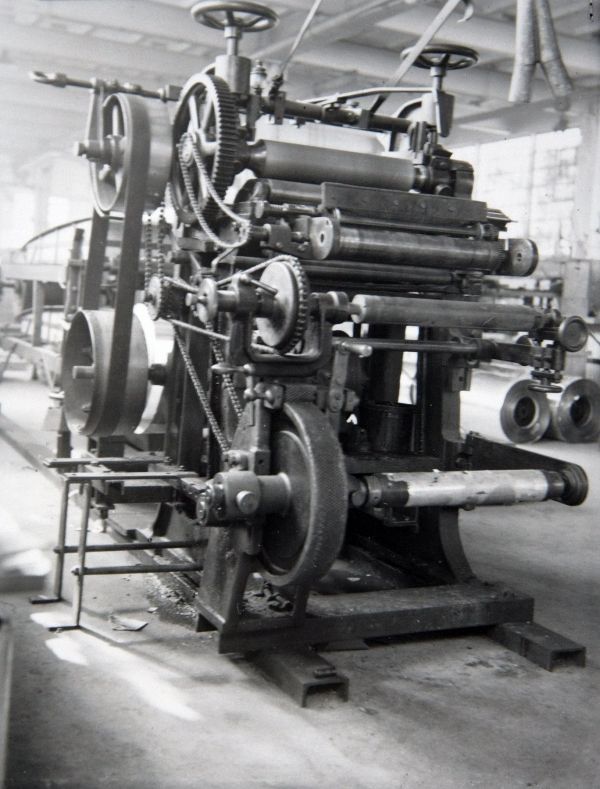

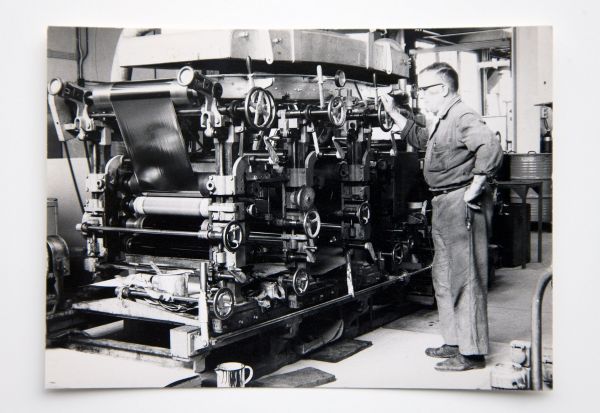

Conceived as a replacement for tin foil, Robert Victor Neher took out a patent in 1910 for the continuous rolling process and opened the first aluminium rolling plant in Kreuzlingen, Switzerland, and by 1911 Bern-based Tobler began wrapping its chocolate bars in alufoil including the unique triangular chocolate bar, Toblerone. And by 1912 alufoil was being used by Maggi to pack soups and stock cubes.

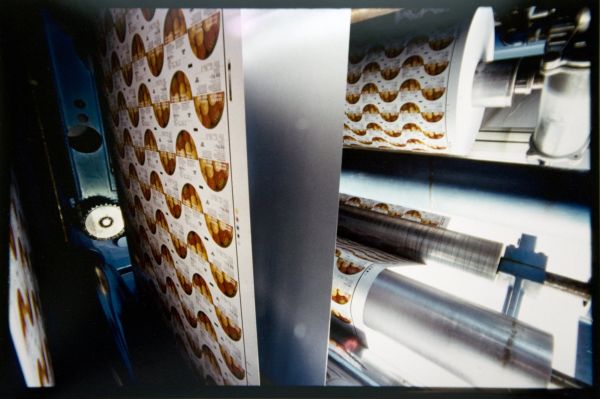

Over its history converters, brand owners, retailers and ultimate consumers have all benefited from alufoil's unique barrier properties which provide a total block to light, moisture and aroma. Today it is used in every conceivable market from food and drink to pharmaceuticals. Applications include aseptic beverage cartons, sachets, pouches, lids, wrappers, blister and strip packs, foil containers and much more. And coming up over the horizon are even more markets and resource efficient options. These include microwaveable containers gaining a foothold throughout Europe and fascinating and technically innovative applications for pharmaceutical foils.

The Age of Convenience and Resource Efficiency

Successes in light weighting of alufoil which had begun in the eighties led to material savings of more than 30% in the new millennium, and in turn this has provided growth in markets for resource efficient packaging options.

Today alufoil's unique barrier properties are being merged increasingly with flexible films to create lightweight packs with excellent preservation properties and this has been instrumental in their use for a number of exciting new and expanding markets. To name just a few, pouches for everything from pet food to drinks; lidding applications; technically innovative solutions for pharmaceuticals; and the increasing acceptance of alufoil as a microwave safe material.